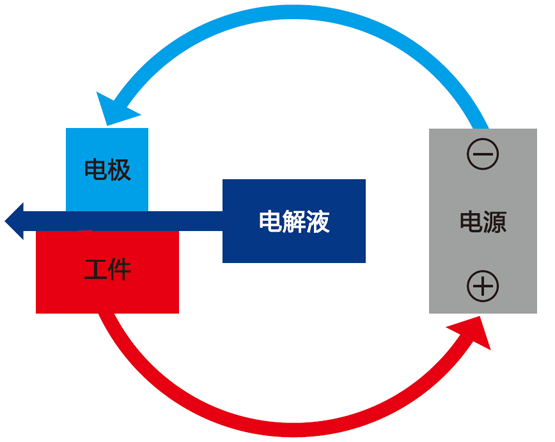

PECM (Precise electrochemicalmachining) refers to the precision electrolysis process. As weknow, a electrolysis system consists of DC power supply, cathode, anode andelectrolyte. As to PECM, the workpiece acts as the anode,and the toolacts as the cathode. When the gap been filled of electrolyte between anode andcathode becomes small enough, the phenomenon of electrochemical dissolutionwill occur at the surface of anode because of metal atoms lose electrons and get intoelectrolyte. In this case, the workpiece can be gradually shaped , and thecathode remains unchanged. The material of workpiece can be removed by electrochemicalmachining regardless of its hardness or mechanical properties.